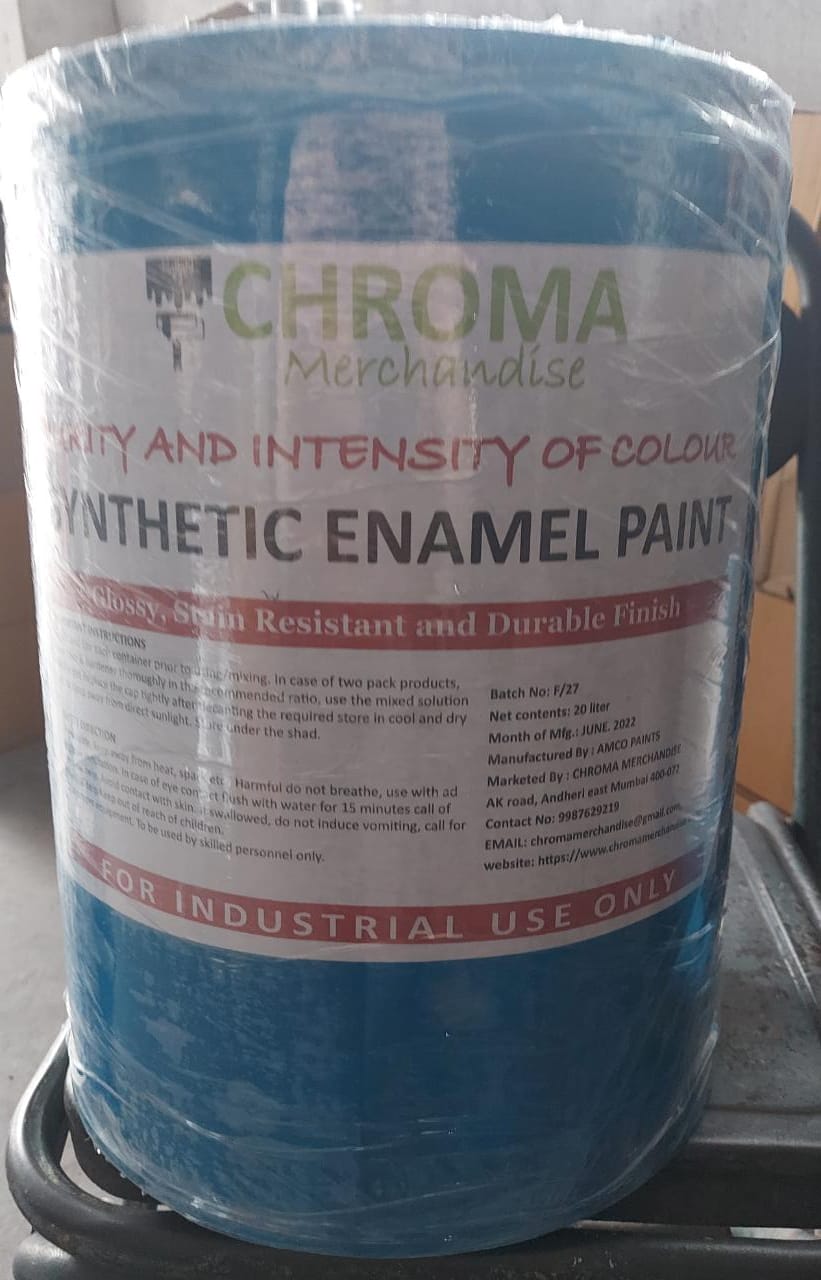

Synthetic Enamel Paint TDS (C)

Product description: Single pack, silicone resin based, heat resisting coating.

DIRECTIONS FOR USE: Surface Preparation

Explore the Technical Data Sheet (TDS) for Synthetic Enamel Paint (C). Discover product details, key specifications, application instructions, drying times, and coverage for long-lasting, high-gloss finishes on metal, wood, and walls in Mumbai, Maharashtra, India

Ready to Start?

If you have any questions, feedback, or inquiries, please feel free to reach out to us using the information below.

Ask Question