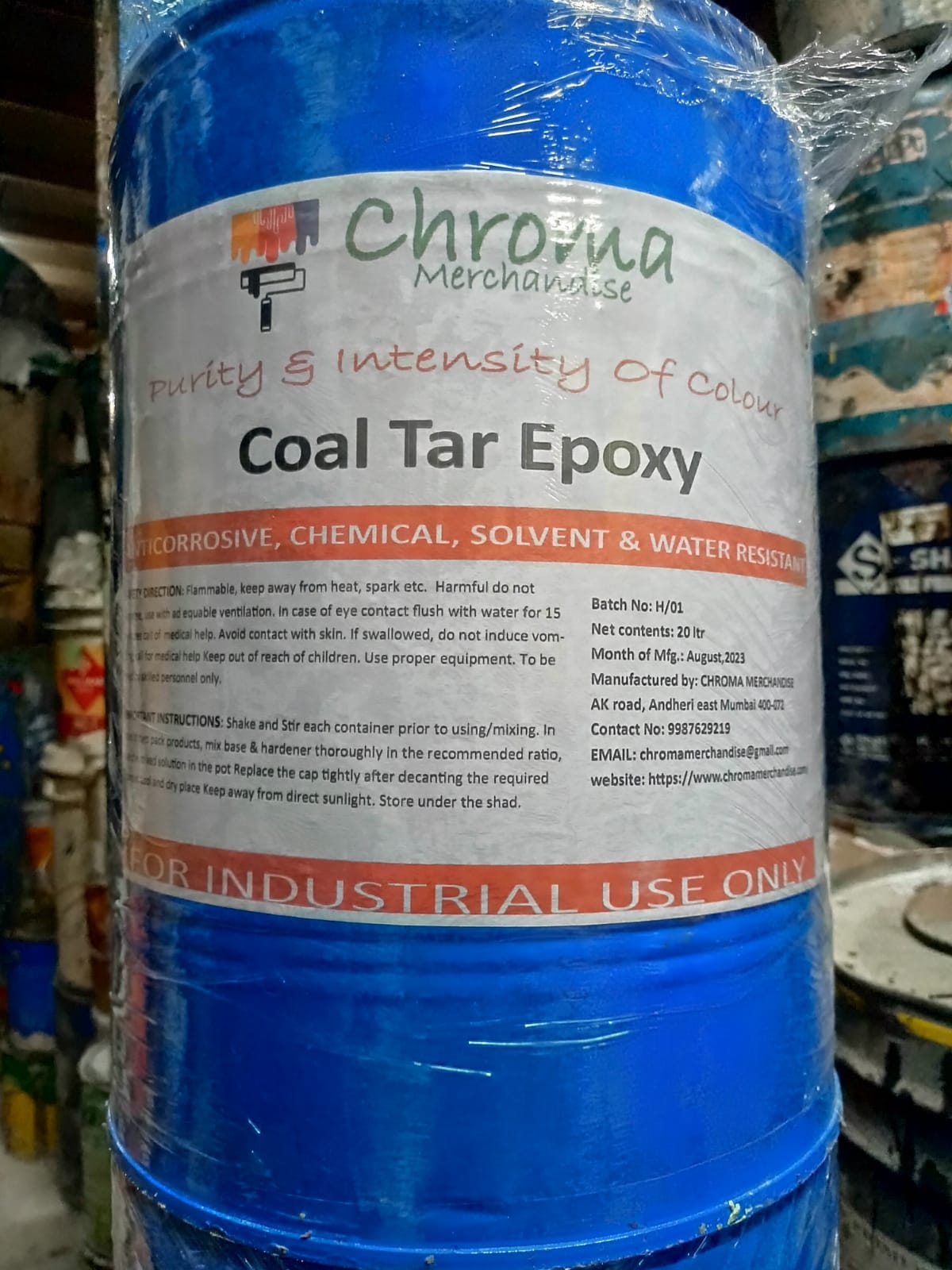

Coal-tar epoxy

Product description Renowned high build coal tar epoxy polyamide for protection of steel and concrete in single or twocoat applications in a broad variety of aggressive industrial applications.

General Surfaces must be clean and dry. Employ adequate methods to remove dirt, dust, oil and all other contaminants that could interfere with adhesion of the coating.

SteelImmersion: SSPC-SP10 Non-Immersion: SSPC-SP6 SSPC-SP2 or SP3 as minimum requirement. Surface Profile: 2.0-3.0 mils (50-75 micron).

Concrete or CMUConcrete must be cured 28 days at 75°F (24°C) and 50% relative humidity or equivalent. Prepare surfaces in accordance with ASTM D4258 Surface Cleaning of Concrete and ASTM D4259 Abrading Concrete. Voids in concrete may require surfacing.

MixingPower mix separately, then combine and power mix for a minimum of two minutes. DO NOT MIX PARTIAL KITS.

ThinningUp to 10 oz/gal (8%) w/ #10 Up to 25 oz/gal (20%) w/ #10 for the first coat application to concrete. Use of thinners other than those supplied or recommended by Carboline may adversely affect product performance and void product warranty, whether expressed or implied

APPLICATION:This is a high solids coating and may require adjustments in spray techniques. Wet film thickness is easily and quickly achieved. The following spray equipment has been found suitable and is available from manufacturers such as Binks, DeVilbiss and Graco.

Conventional Spray: Pressure pot equipped with dual regulators, 3/8” I.D. minimum material hose, with 50' maximum material hose.086” I.D. fluid tip and appropriate air cap.

Airless SprayPump Ratio: 30:1* GPM Output: 3.0 (min.) Material Hose: ½” I.D. (min.) Tip Size: .023-.035” Output PSI: 2100-2500 Filter Size:30 mesh *Teflon packings are recommended and available from the pump manufacturer

Use1) Use a medium bristle brush 2) Use a short-nap synthetic roller cover with phenolic core

Force Cure:FORCE CURING recommended for thicknesses 25-35 mils DFT Hold substrate temperature at 150°F for 8 hours and material will be ready to handle and ready for immersion service

Safety:Read and follow all caution statements on this product data sheet and on the SDS for this product. Employ normal workmanlike safety precautions. Hypersensitive persons should wear protective clothing, gloves and use protective cream on face, hands and all exposed areas.

Caution:This product contains flammable solvents. Keep away from sparks and open flames. All electrical equipment and installations should be made and grounded in accordance with the National Electric Code. In areas where explosion hazards exist, workers should be required to use non-ferrous tools and wear conductive and non-sparking shoes.

Coal-Tar Epoxy (TDS)-C is a high-performance, heavy-duty coating designed for extreme corrosion resistance in aggressive environments. With exceptional adhesion and resistance to water, chemicals, and abrasion, this epoxy is ideal for pipelines, tanks, marine structures, and wastewater facilities. View the technical data sheet (TDS) for detailed application and performance specifications. Mumbai, Maharashtra, India

Ready to Start?

If you have any questions, feedback, or inquiries, please feel free to reach out to us using the information below.

Ask Question