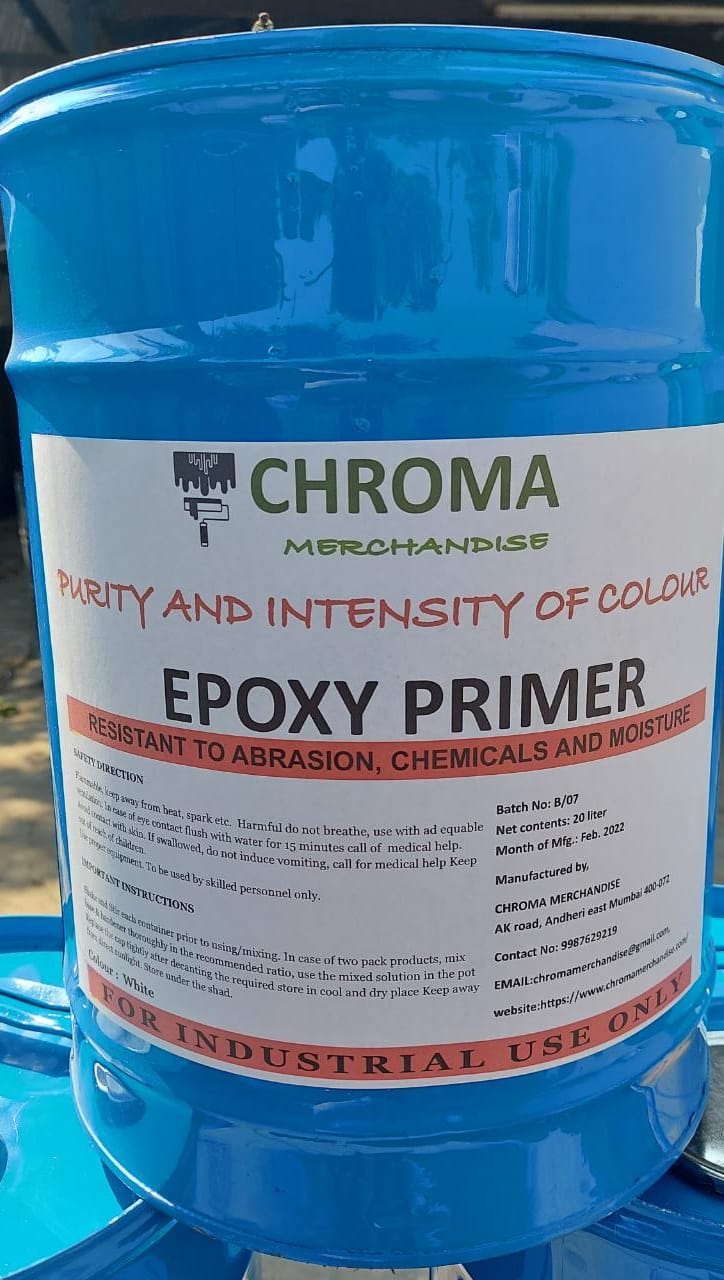

Epoxy Primer (TDS)-C

Product DescriptionTwo component polyamide cured epoxy coating.

Direction for Use:

Pack Size (Base: 16 L & Hardener: 4L).

Epoxy Primer (TDS)-C is a high-performance primer designed to enhance adhesion and provide exceptional corrosion resistance for industrial applications. Suitable for metal and steel surfaces, this primer offers a reliable base coat for lasting protection against wear and harsh environments. View the technical data sheet (TDS) for detailed specifications and application guidelines Mumbai, Maharashtra, India

Ready to Start?

If you have any questions, feedback, or inquiries, please feel free to reach out to us using the information below.

Ask Question