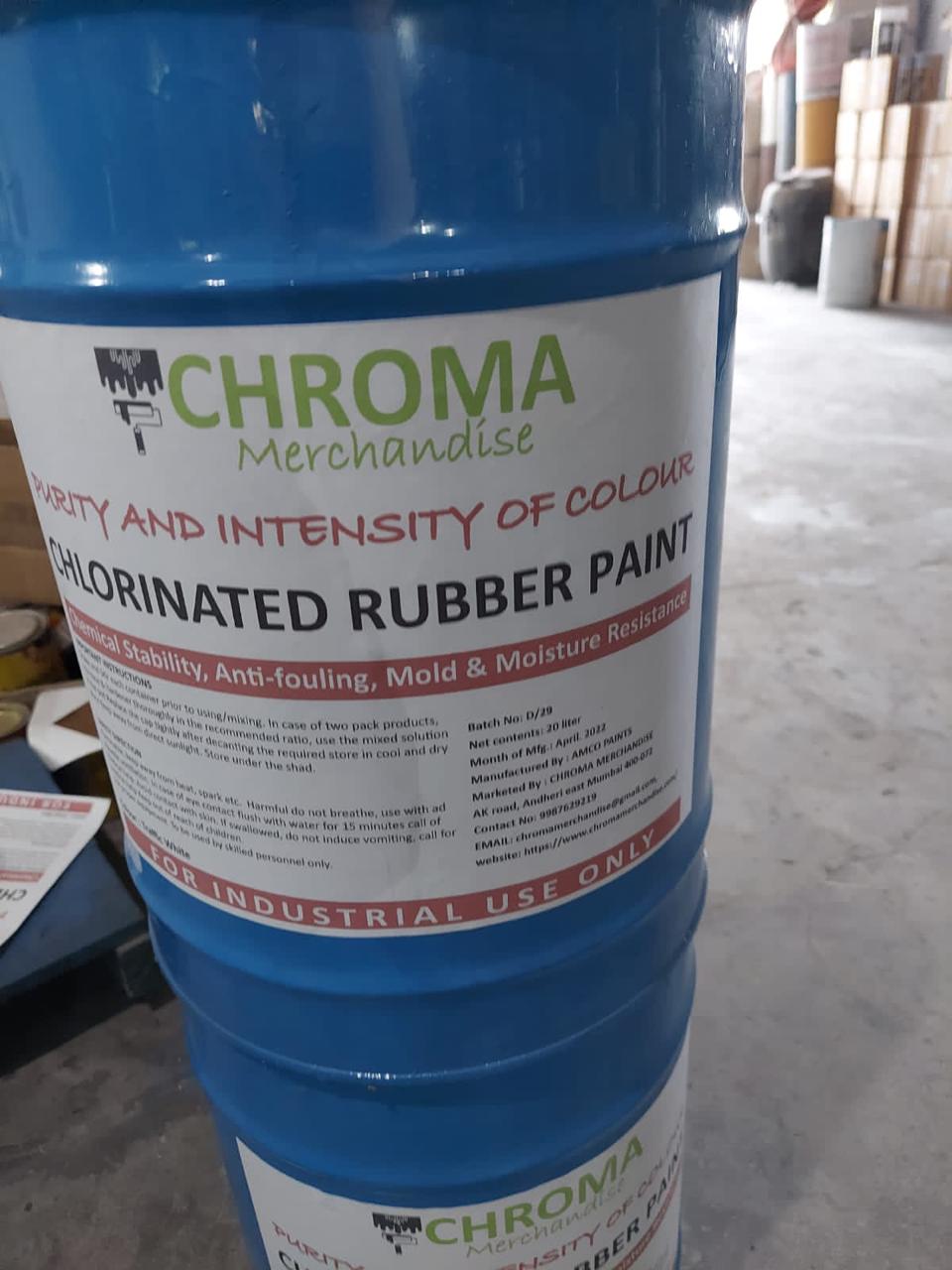

CHLORINATED RUBBER PAINT

Product descriptionChlorinated Rubber Coatings are formulated specifically for application to new or old concrete, or previously painted chlorinated rubber finishes. They offer a proven, cost effective single pack hard satin finish, with outstanding resistance to swimming pool chemicals and salt water.

DurabilityExcellent.

ApplicationBy brush, roller or airless spray. Avoid heavy coats which may result in blistering. NEVER APPLY OVER DAMP SURFACES. Use caution when applying in very hot and/or sunny conditions as this makes application more difficult and may cause blistering. Apply a minimum of 3 coats, preferable 4 coats for best results.

THINNINGThinning is recommended only for the 1st coat, and then not to exceed 5% of Chlorinated Rubber Solvent (CRS) by volume. DRY TIME/RECOAT TIME: Touch dry in 1-2 hours. Recommended recoat, depending on temperature and humidity is 24 hours at the same time of day as the initial coat. Do not paint at temperatures below 10oC or above 30oC, or in humidity levels exceeding 85%.

COVERAGEApproximately 5– 8 m2 /L/ per coat, depending on the type of surface.

CLEAN-UP:Clean all equipment with Chlorinated Rubber Solvent (CRS).

POOL REFILLChlorinated Rubber must be allowed to fully dry before immersed in water. Full solvent release is 7-21 days depending on the weather conditions. Solvent release is not possible once the coating is immersed.

MAINTENANCEEnsure that you let your pool shop know that your pool has a Chlorinated Rubber coating, and our recommended pool chemistry.

Packing Size: 20 LTR

NoteBefore Application Water-proofing Is Must.

Chlorinated Rubber Paint (TDS)-C is a premium protective coating designed for harsh environments, offering excellent resistance to chemicals, moisture, and UV exposure. Perfect for marine, industrial, and swimming pool applications, this paint ensures long-lasting durability on concrete, metal, and masonry surfaces. View the technical data sheet (TDS) for detailed specifications and application instructions. Mumbai, Maharashtra, India

Ready to Start?

If you have any questions, feedback, or inquiries, please feel free to reach out to us using the information below.

Ask Question